Revolutionize Moisture Removal with Acmefil’s ATFD

Dry heat-sensitive and viscous materials efficiently with minimal degradation and maximum performance.

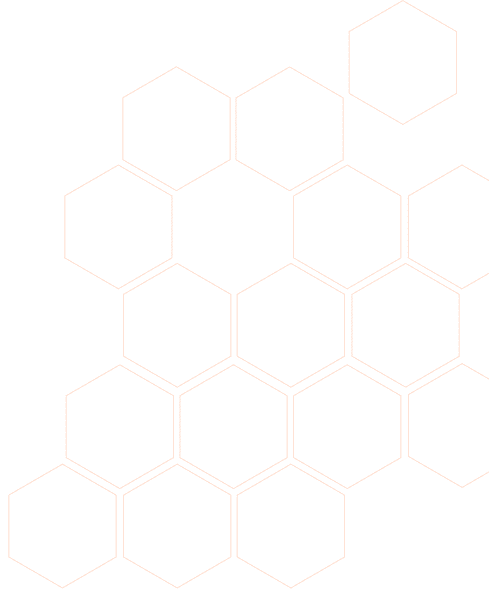

who are we

Acmefil Engineering Systems Pvt. Ltd.

Engineering Excellence Since 1992

Acmefil Engineering Systems Pvt. Ltd., specialize in the design, manufacture, and export of advanced drying and concentrating equipment. With over 800 successful installations across India and a growing global presence, Acmefil has built a solid reputation for innovation, quality, and customer satisfaction.

explore our services

Evaporator Types

Acmefil Engineering System Pvt Ltd. is the leading manufacturers of Evaporators In India

Falling Film Evaporator

A thin film of liquid flows downward along the inner surface of vertical tubes while being heated. The solvent evaporates quickly with minimal thermal degradation. Highly energy-efficient and suitable for continuous operation.

Rising Film Evaporator

In this design, the liquid rises inside vertical tubes due to vapor formation, creating a thin film along the tube walls. It offers good heat transfer and is suited for temperature-sensitive solutions.

Forced Circulation Evaporator

A circulation pump forces the liquid through heat exchangers and flash chambers, ensuring high heat transfer rates even for fouling or high-solids materials. Commonly used in chemical and effluent concentration.

Multiple Effect Evaporator (MEE)

MEE uses a series of evaporators (effects) where vapor from one effect is reused as the heating medium for the next. It drastically reduces steam consumption and operating cost.

Agitated Thin Film Evaporator (ATFE)

A close cousin of the ATFD, the ATFE spreads the feed into a thin film using an internal rotor. Rapid evaporation occurs under vacuum with minimal product residence time, making it ideal for critical compounds.

Vacuum Evaporator

Operates under reduced pressure to lower boiling points, protecting the product from thermal degradation. Often integrated with ATFDs or MEEs for complete drying.

Contact Information

- acmefilespl@gmail.com, info@acmefil.com

- +91 9825013851

Address Details

- Plot No. 535, Phase II G.I.D.C, Vatva Ahmedabad - 382 445 Gujarat - INDIA

get in touch

Request A Quote

We would love to hear from you and also discuss any thing about a project. Get in touch also if you have the queries and we will get back to you soon.

here to lead others

Our Clients

faq

Most Common FAQs

ATFDs are ideal for drying heat-sensitive, viscous, and concentrated materials such as slurries, pastes, pharmaceutical APIs, food extracts, effluent concentrates, and chemical intermediates.

Unlike traditional dryers, ATFD forms a thin, continuously agitated film on a heated surface, which allows for faster heat transfer, shorter residence time, and minimal thermal degradation—making it highly suitable for delicate and high-viscosity products.

Typical utilities include steam or hot oil for heating, vacuum system, and cooling water for the condenser. Utility specifications depend on the size and capacity of the system.

Yes, ATFDs can be customized with corrosion-resistant materials such as SS316L, Hastelloy, or PTFE linings to handle corrosive or abrasive products safely and efficiently.

ATFDs are primarily designed for continuous processing, but can also be adapted for batch operations in smaller-scale or specialized applications.